- -30.85%

Practice

Practice

Laboratory

Laboratory

Training

Training

In-office 3D press-on dental printer for definitive restorations

SprintRay's MIDAS is the ultimate solution for in-office restoration making, being the first 3D dental press dental printer for permanent restorations!

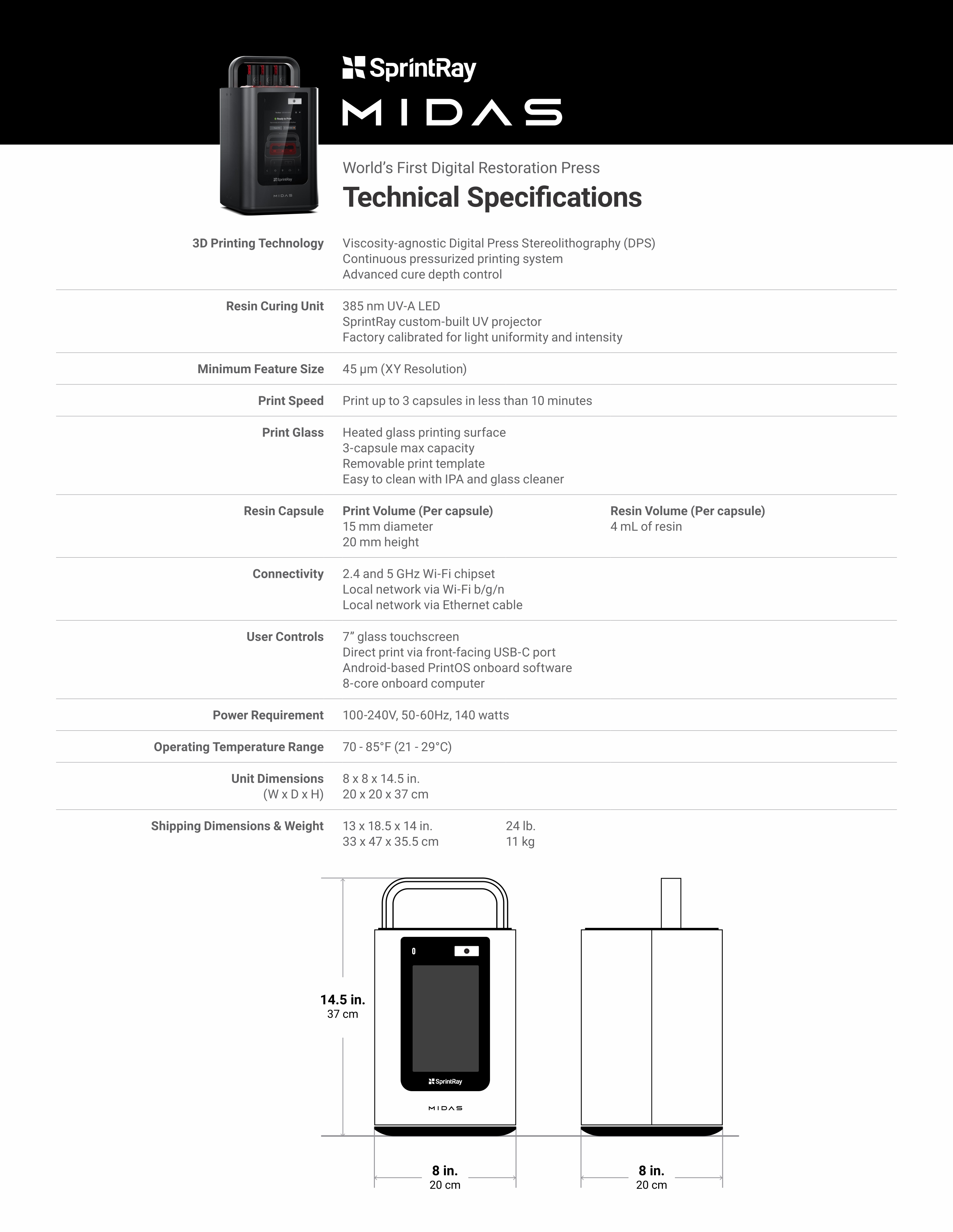

It is the product of the most revolutionary 3D printing technology for dentistry. MIDAS uses digital stereolithography (DPS) - patent-pending technology, to overcome the challenges of printing viscous materials with high filler content.

This technology replaces the resin, reservoir and build platform with a resin capsule. This enhancement allows Midas to print with high-filler resins that are too viscous to be used on a conventional 3D printer.

ADVANTAGES

+ No viscosity limitations

+ Artificial intelligence assisted design

+ It is an extremely compact device with very small dimensions - 20cm x 20cm x 37cm

+ It has 3 cartridge slots, so you can print multiple items at once

+ Zero training, no maintenance

+ Simplified workflow

+ Extremely quiet

FAST

Digital Stereolithography (DPS) allows you to 3D print high fill composite restorations in minutes

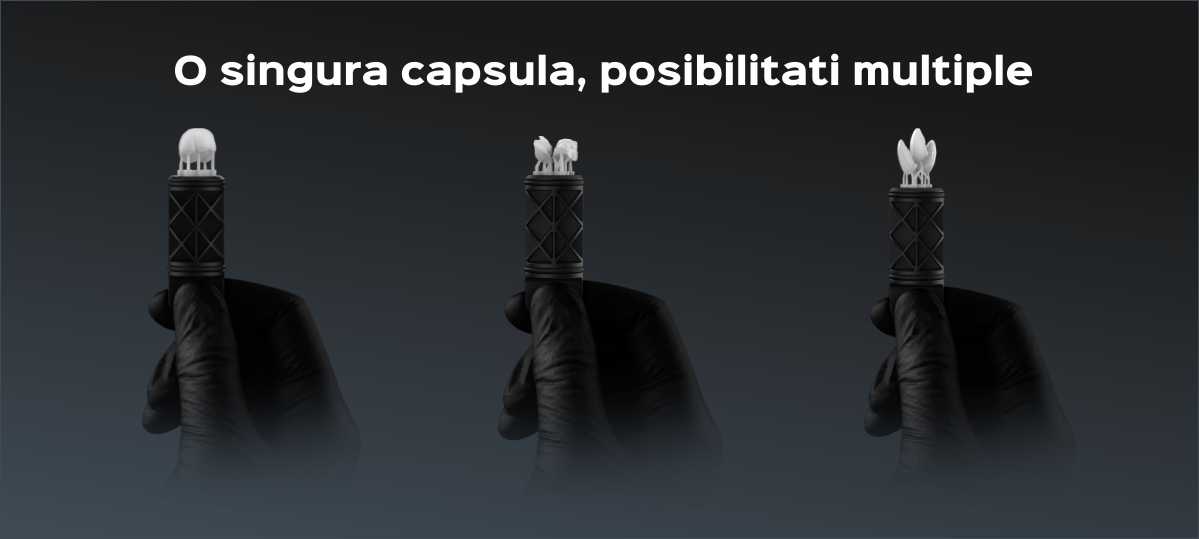

The MIDAS Resin Capsule is a single-use product that replaces essential elements of previous printing systems - the build platform, reservoir and resin.

1. Full-contour crowns with realistic aesthetics and mechanics due to extremely high filler content

Posterior crowns

Anterior crowns

Crowns on implants

2. Complex shapes imprinted with perfect precision - fabricate up to 2 inlays / capsule

Fillings

Onlays

Inlays

3. Print up to 3 incredibly thin and strong veneers with a single capsule for minimally invasive aesthetic treatments

No-prep veneers

Prepped veneers

Anyone can print a restoration on the Midas, you don't necessarily have to be the dentist.

Because it uses resin capsules instead of cumbersome bottles and reservoirs, printing is as simple as brewing your morning coffee

Step 1: Scanning

Each Midas capsule is coded with material type, shade, manufacturing information and expiration date. When it's time to print, simply scan the capsule using the barcode scanner.

+ Automatic medical device tracking

+ Resin and color detection

+ Eliminate the risk of errors

Step 2: Positioning

MIDAS has three print slots on the heated print window. After scanning, the on-board computer will tell you where to place the cartridge.

+ Up to 3 capsules can be printed simultaneously

+ Capsule location detection

+ Fully guided workflow

Step 3: Press

MIDAS will start pressing after you have scanned and placed all the capsules to make a job. The print loop will slowly lower as the resin hardens.

+ Printing in less than 9 minutes

+ Clean workflow

Step 4: Remove the capsule

Remove the capsule from the print window. Pull the flap on the manufacturing platform to remove it from the capsule. The restoration is ready for post-processing.

And done!

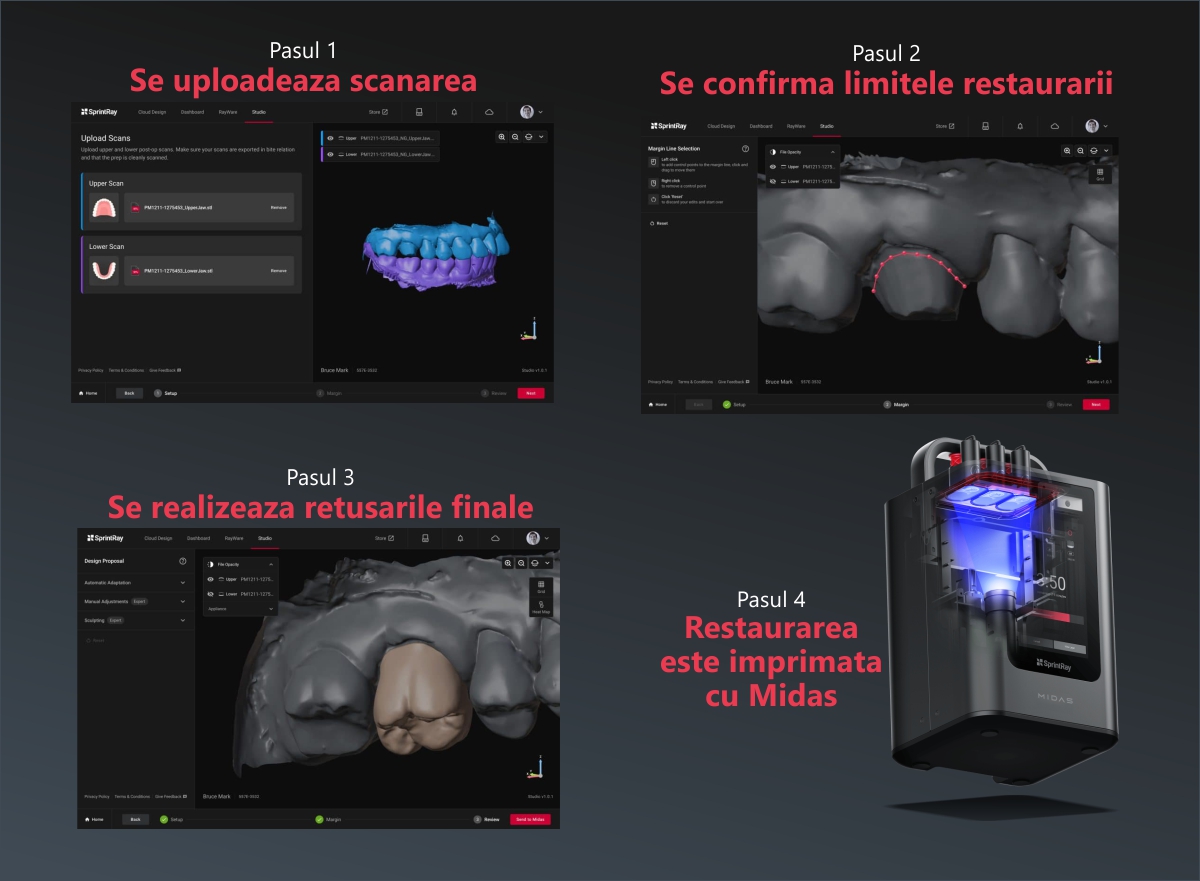

Step 1: Upload the scan

AI Studio takes the upper and lower arch scans

Step 2: Confirm restoration limits

Automatically adjusts the boundary line to get the perfect crown

Step 3: Final retouches are made

Aesthetic adjustments and final positioning are made.

Step 4: The restoration is printed with Midas

The design of the restoration is sent directly to Midas, and the impression will be made in 10 minutes maximum!

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent

In-office 3D press-on dental printer for definitive restorations

check_circle

check_circle