- Sold out

Practice

Practice

Laboratory

Laboratory

Training

Training

Compact 5-axis milling machine with wet and dry milling for CAD-CAM discs and blocks

The COBRA6XD dental milling machine is a compact 5-axis wet and dry milling machine for zirconia, PMMA, wax, composite, titanium, cobalt chrome, ceramic and lithium disilicate.

Features:

- Simultaneous 5-axis milling

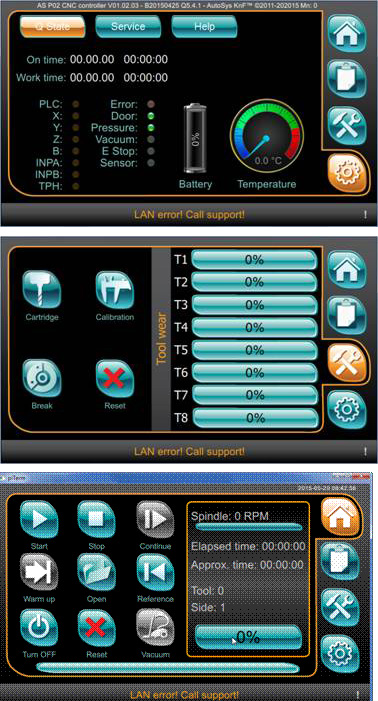

- State-of-the-art control system with integrated computer

- 8" touchscreen user interface, easy and intuitive navigation, easy to access remote assistance thanks to pre-installed TeamViewer application

- Actual accuracy less than 0.01mm

- X-Y-Z axis motion with linear guides and servo control with encoder and stepper micromotors (control at 0.001mm per rotation, ensuring smooth motion in all axes)

- "A" axis angle: +/- 30 degrees

- "B" axis rotation: 360 degrees

- Up to 30 cutters in interchangeable magazines (6 cutters/magazine)

- Automatic cutter change

- Automatic cutter check by high precision optical sensor

- Compatible with standard 98.5mm diameter discs with manual change

- Block holder included (with 4 different block/hub mounting positions)

- Prefabricated implant post holder (with 6 different post mounting positions)

- High speed milling (500W, 60.000RPM motor, spindle with hybrid ceramic bearings)

- Chuck diameter: for 3 or 4mm spindle cutters - compatible only with specially calibrated PiDental cutters

- Cooling system with separate tank and pump: included

- Requires connection to compressed air/compressor, available separately: dry, clean air, working pressure 6bar, max. consumption 50l/min

- Requires connection to vacuum cleaner, available separately

Compact and economical:- dimensions: 578 x 681 x 674mm (WxHxD)- weight 85kg- max consumption 600W

CAM software included: PiCAM - a solution developed 100% in-house by PiDental, optimized for PiDental CAD-CAM systems.PICAM is now INTEGRATED in EXOCAM* *(requires Exocad "Nesting" module - not included in the offer)

Thanks to the close collaboration with EXOCAD/EXOCAM, a complete and fully integrated solution has been developed for users.Called PiCAM, it offers numerous benefits and options, including:

1. A streamlined implementation process, allowing a seamless workflow from start to finish.

2. Open, STL file-based system

3. Familiar Exocad interface ensures that users can quickly adapt to the new software without a steep learning curve.

4. PICAM is designed to work seamlessly with standard keyboard and hotkeys, making it easier and faster to use.

5. The software takes into account all parameters set during the planning phase, such as preparation edges, screw channels, etc., ensuring greater accuracy and precision in the final product.

6. Multi-layer information display provides a clear and comprehensive view of the milling process and its progress.

7. Positioning in material blocks allows for more efficient use of materials, reducing waste/loss and increasing productivity and efficiency.

8. Overview of the milling process, allowing better control and management of the production process.

9.Disc management ensures the right materials are used for each project, reducing the risk of errors and inconsistencies.

10. Automated cutter path creation simplifies the milling process and reduces the risk of errors or inconsistencies in the milling process.

11. Milling path display and milling simulation allows users to visualize the milling process before it begins, ensuring greater accuracy and precision in the final product.

PiCAM® software

Developed 100% by PiDental

Fully open, STL-based

Accepts data from any type of CAD software

Economical design process

Ergonomic, easy to use

Occlusal pin function and stabilizer for large points

Connecting rods can be thinned or cut automatically at the end of milling

Fast generation process

Simulation option

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent

Compact 5-axis milling machine with wet and dry milling for CAD-CAM discs and blocks

check_circle

check_circle