NiTi rotating needles with positive cutting angle and variable depth coils. 6 needles/box.

| Produs | Referinta | Stoc | Pret | |

|---|---|---|---|---|

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .02

Length: 25 mm

Size: #15

|

825-2155 | 179 RON | | |

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .02

Length: 25 mm

Size: #20

|

825-2205 |

134.25 RON

179 RON |

| |

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .02

Length: 25 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 21 mm

Size: #15

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 21 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #15

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #15-40 ASS

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #20

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #20

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #30

|

825-4305 |

134.25 RON

179 RON |

| |

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #35

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #40

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 25 mm

Size: #60

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 30 mm

Size: #15

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 30 mm

Size: #20

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .04

Length: 30 mm

Size: #40

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 21 mm

Size: #25

|

178 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #15

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #15-40 ASS

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #20

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #30

|

825-6305 |

134.25 RON

179 RON |

| |

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #35

|

825-6355 |

134.25 RON

179 RON |

| |

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #40

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #45

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #50

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #55

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .06

Length: 25 mm

Size: #60

|

178 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .08

Length: 17 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .08

Length: 21 mm

Size: #25

|

178 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .08

Length: 25 mm

Size: #25

|

830-8255 |

134.25 RON

179 RON |

| |

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .10

Length: 17 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .10

Length: 21 mm

Size: #25

|

178 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .10

Length: 25 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .12

Length: 17 mm

Size: #25

|

179 RON | | ||

|

Ni-Ti K3 Rotating needles Kerr Endo

Taper: .12

Length: 21 mm

Size: #25

|

179 RON | |

Designed for efficiency!

9 reasons why K3 is more efficient

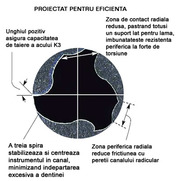

1. Positive cutting angle

2. Variable angle coils

3. Wide radial peripheral support zone

4. Radial discharge zone

5. Short Axxess handle

6. Third coils

7. Variable depth coils

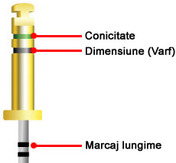

8. Simplified colour markings (taper, peak, length)

9. Safe-end cutting edge

1. Positive cutting angle

The cutting efficiency of a tool is dependent on the cutting angles that the coils have. The cutting angle is determined by the imaginary line passing through the centre of the needle and the cutting face of the spiral. Conventional and Profile needles have a negative cutting angle, resulting in a "shaving" rather than cutting action.

Dentine being dense and somewhat resilient, cutting and removing it with negative cutting angles is difficult and very inefficient. The ideal cutting angle is slightly positive, as too great a tilt would result in too aggressive removal of the dentine ("undercutting"). K3 has a slightly positive cutting angle for efficient cutting. Dentin dislodged by the K3 needle is easily removed from the working area thanks to the variable angle coils.

2. Variable angle coils

Once the tool has started cutting into the dentine, the debris must be removed. This allows further cutting into the dentine. Compression occurs when the debris is trapped between the canal walls and the instrument coils. Note that when the needle rotates in the canal, more debris collects in the crown area of the instrument. If there is no more space to channel the detritus, the instrument will jam. Dentine debris generated by the K3 are easily removed from the working area thanks to the variable coil design. In short, the inclination of the coils increases from the tip to the handle.

3. Peripheral radial wide support area

The best way to explain this feature is through the blade support.

The resistance, in most needles, is given by the mass of the material in the central area of the instrument shaft, and not by the radial peripheral area, near the blade of the barrel.

To resist torsional forces, an endodontic needle should have sufficient peripheral strength.

The blade holder (the area supporting the coil blade) is a critical element in the design of the instrument. The smaller the blade holder (less material behind the blade), the less resistant the instrument is to torsional forces. For example, the Profile needle does not have a maximized peripheral mass. The superior peripheral strength of the K3 needle is achieved by increasing the mass behind the blades.

To reduce friction between the needle and root canal walls, K3 still has a reduced radial perimeter (the contact area between the needle and the canal walls). The increased peripheral mass of the K3 needle prevents crack propagation and reduces the chance of breakage or deformation due to torsional forces.

Radial discharge area

The frictional resistance of the needle is proportional to the surface area of the peripheral radial zone that comes into contact with the root canal walls. A wide peripheral zone, without discharge, would cause greater friction. The K3 has a significantly more sophisticated design. In addition to reducing friction, the peripheral unloading zones have another role. Many needles have no control over the cutting depth of the coils in dentin. The harder you push towards the apex, the deeper the blades will cut. The peripheral discharge area of the K3 needle helps control the depth of cut. This protects the needle from over-cutting and separation (breakage).

5. Axxess Handle

In endodontics, the most important thing is: access. The K3 needle handle facilitates the user's access to the posterior region of the oral cavity. K3 needles are 4mm shorter than competitors' needles, but the length of the active part is the same. Because of the shorter overall length, the operator has much better visibility than using a normal contra-angle piece.

6. The third coil

The main purpose of this area is to prevent the needle from "screwing" into the channel. This loop, without the peripheral discharge zone, allows the operator much better control of the instrument by centering and stabilizing the instrument.

7. Variable depth coil

The ratio of shaft diameter to outside diameter is greatest at the tip, where strength is most important. This ratio decreases uniformly as the thread increases in taper, resulting in a greater thread depth, thus increasing the flexibility of the needle but maintaining the strength.

An additional benefit is more efficient removal of dentinal debris.

8. Simplified colour markings

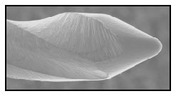

9. ''Safe-end'' non-cutting tip

The K3 tool's smoothing tip follows the canal, avoiding punctures, false paths or other unpleasant surprises.

The introduction of Nickel Titanium (Ni-Ti) rotating needle instrumentation revolutionised endodontics. For more than 5 years, the endodontic community has accepted these instruments as a new standard, changing the relevance of standard ISO steel instruments in endodontic procedures.

Pioneers of Ni-Ti instrumentation include Dr John MacSpadden and Ben Johnson. They both introduced the concept of manufacturing and using Ni-Ti instruments with a higher taper compared to the ISO taper (0.02). Higher taper instruments are available from 0.04 to 0.12.

The advantages of higher tapers are:

- more efficient preparation

- mechanically actuated

- no finger pain

- fewer tools used for preparation

- superior preparation for better filling

Instrument diameter increases by 0.02mm for every millimetre of length, from D1 to D16, on a standard ISO taper needle.

The diameter of a 0.06 taper instrument increases by 0.06mm for each millimetre of length from D1 to D16.

In addition, the physical properties of Ni-Ti allow these highly tapered needles to maintain their flexibility to optimally handle even the most curved canals.

A steel tool with a large taper would be very stiff and unusable in curved canals.

Presentation: box 6 needles